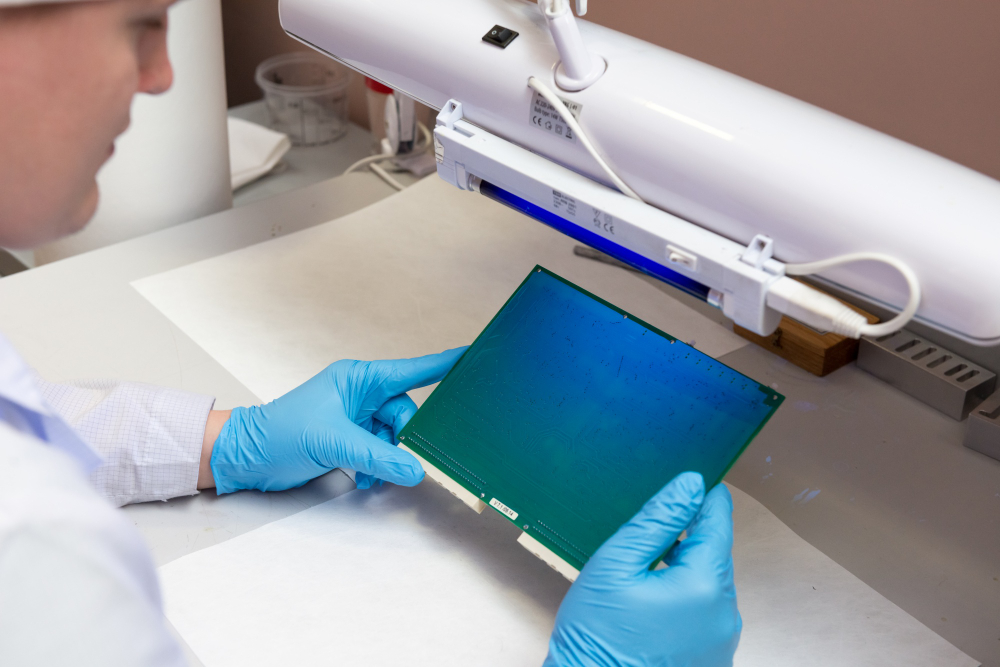

In the healthcare business, communication on clarity, accuracy, and resistance is grounded in serious and grave concerns. One area where this is specifically subject to negotiation is related to the employment of medical device pad printing for the longevity of readability of the symbols, dosage marks, serial numbers, and branding that are printed on a device. From disposable instruments to low-end implants, printed materials will be faced with sterilization, wear, and reuse many times over, yet without fading or smearing.

And all these requirements are served by pad printing, which excels in marking precision on complex shapes and small areas. Unlike traditional methods of printing, pad printing can be conveniently geared to flat, sloped, textured, or awkwardly shaped parts. This implies that the printings will always be neat and evenly spread so that they can fulfill the function as well as regulatory requirements regarding patient health and product tracking.

Medical Printing Services for Safety

Reliable medical printing services that collaborate with everything, and that is much more than aesthetics. The usability, compliance, and risk reduction of technology would be significantly impacted. Clearly laid instructions for practitioners’ think-emphasis devices, indications, and high-pressure error-free environments constitute labeling.

In medical regulated settings, printed information must remain throughout chemical exposure, heat, and tedious cleaning, but it is. Several biotech inks, their controlled use in printing processes, and rigorous lab tests are put into place to ensure printed images remain crisp and easy to read. However, if their format meets standards defined by medicine, their trust is boosted with all companies, clinicians, and end users.

Critical factors for consideration, which are found in medical printing, include:

- High-contrast, legible markings used for critical information

- Compatibility with medical-grade materials and coatings

- Ability to withstand sterilization, abrasion, and chemicals

- Consistency in high-volume production runs

These elements all add together to ensure that, from factory floor to patient care, devices perform exactly as designed.

Medical Device Printing Standards

The essence of Medical Device Printing is compliance. In practice, regulatory guidelines call for accuracy, permanence, and repeatability. Every print must serve purposes such as product identification, traceability, and uninterrupted utility while not worsening the ability of the product to be used.

Extreme attention towards compliance, alongside supreme paper printing technology, makes it possible to serve a market need without diminishing quality or compliance. Machinery that abides by particular regulations with an element of high-speed printing can provide unmatched, exact coding or markings, the ultimate quality concerning international executability.

Trusted Medical Device Printing Partner

Compliance and precision become key in working with seasoned professionals. Pad Print USA masters in high-quality medical device pad printing and reliable medical printing services, which are pretty well-suited to the healthcare sector. Focusing on accuracy, permanence, and consistency, they provide an added service to support manufacturers in apprehensive markets.

Partner with Pad Print USA to elevate your medical device printing—get started today.