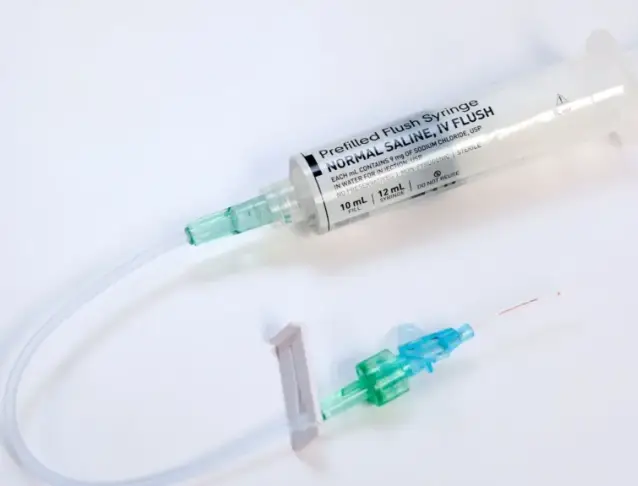

The necessity of industrial precision, definitional clarity, and mechanical robustness is particularly critical for the medical manufacturing environment. The dimensions, descriptions, or symbols marked on devices bear an unmistakable meaning for all professionals and health administrators-a symbol to guide an operator in certain situations during their practice of job roles to help ensure the safety of vulnerable patients. Hence, high-quality surface-sensitive medical device pad printing is now defining the field of healthcare production.

In response to ever-advancing needs for medical enhancements in terms of shapes, sizes, and complexity, indestructible imprints are in high demand. This is why manufacturers and producers turn to state-of-the-art medical device printing for their surgical and diagnostic tools, implant components, and many new designs.

Reliable Print Quality for Complex Devices

In medical engineering, there is a sense of consistency in how printing processes can accommodate product format and other technical requirements, which makes medical devices pad printing unique. This enabled the imaging into the groove and high surface texture in the printing of diagnostic techniques and instrumentation.

Expressed in a different perspective, healthcare professionals depend on devices that can be read after several sterilization cycles. That’s where dependable medical printing services come into play. The use of durable inks, controlled processes, and advanced transfer technologies ensures that labels will survive and that errors and safety lapses are prevented.

Key Features of Professional Printing

This form of high-quality Medical Device Printing has to provide additional value to manufacturers. The process should improve usability, compliance, and accuracy in proper sequence—three critical factors within a health care system.

Accuracy in Printing:

- For safe use, correct labeling will be maintained.

- In essence, it respects compliance in its field.

- Printing is achieved regardless of curvature or porosity.

- Like a permanent marker, the printing on devices must resist sterilization.

- Designates the product and makes it easier to be identified.

- Act Items responsibly to assure quality and consistency of high-volume repeat jobs.

When a firm settles on hiring medical printing service providers, it knows that not only graduation but also performance on a solid mark will be verified firsthand on every piece as it leaves its shop.

Enhancing Safety Through Better Markings

Clear, obvious markers enable medical personnel to perform precise procedures under stress. Calibration scales, indicators, measurement gradations, and various brand identifiers comprise the universe of medical device pad printing. Highly unacceptable are instances of even the slightest fading, asymmetric misalignment, or poor resolution, as they can block device operation and compromise safety or effectiveness.

Modern print technology ensures device readability and withstands handling, autoclaving, and exposure to a wide range of chemicals throughout use. As such, printing should play a much bigger role in producing medical devices than merely an embellishment on the final product. When print quality starts supporting the device’s function, the healthcare provider’s potential is contrary to what one would expect.

Trusted Printing Support for Manufacturers

For tough, high-precision print needs in their equipment, companies can choose an expert service based on modern technology from Pad Print USA. In their expert Medical Device Printing, their team ensures a reliable final product that is tough enough to withstand the rigors of the clinical environment.

Pad Print USA caters to a myriad of printing requirements, ranging from safety, accuracy, and consistency.